Polyester Recycling: Managing Chemical Risks for a Circular Future

As the fashion industry accelerates toward a circular economy, polyester recycling is positioned as a critical solution. But recycling alone isn’t clean unless the chemistry is safe. To achieve true, scalable circularity, the industry must address the chemical risks in polyester recycling.

Why Polyester Recycling Matters

Polyester’s share of the global fiber market has grown from approximately 15% in 1975 to over 54% today — and it is projected to reach 67% by 2030. Without effective recycling systems, the industry will continue to depend on virgin, fossil-based inputs and face mounting environmental challenges.

Regulatory pressure is also intensifying:

- EU Ecodesign for Sustainable Products Regulation (ESPR): introduces the Digital Product Passport (DPP) and mandates recyclability and recycled content.

- EU Waste Framework Directive: requires separate textile waste collection and Extended Producer Responsibility (EPR).

- California SB 707: the first mandatory U.S. EPR scheme for textiles, requiring brands to comply by 2030.

- EU REACH restrictions: expanding to cover skin-sensitizing dyes, PFAS, and other substances common in textiles — creating major compliance challenges and significantly increasing the need for advanced chemical recycling technologies.

For brands and suppliers, polyester recycling is no longer optional — it is becoming a compliance requirement, a sustainability differentiator, and a market advantage.

(Learn more in our article on PFAS in clothing).

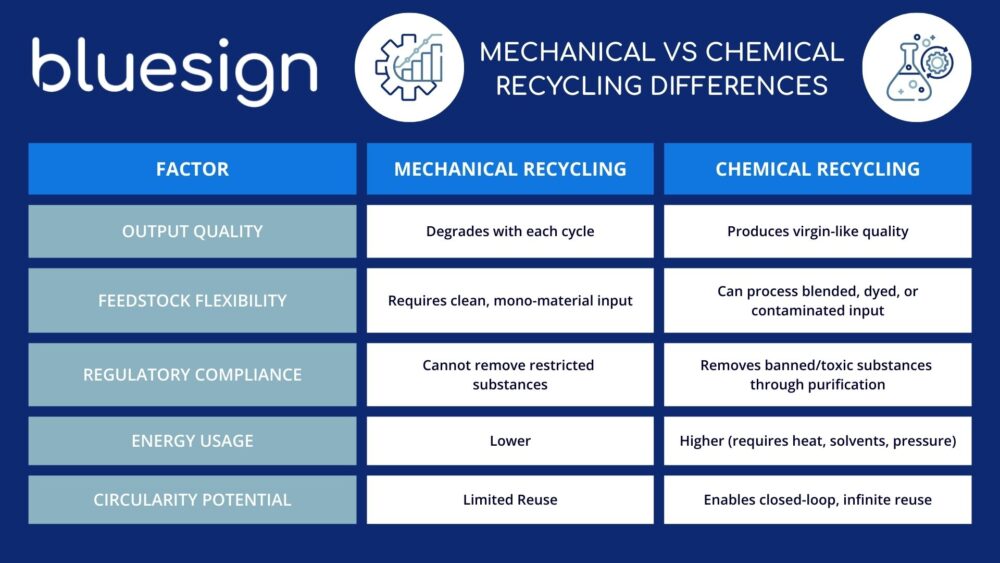

Mechanical vs. Chemical Polyester Recycling

Recycled polyester (rPET) is currently produced through mechanical recycling or chemical recycling. Each approach comes with benefits and risks.

Mechanical Recycling

- Process: polyester bottles or textiles are collected, cleaned, shredded, melted, and spun into new fibers.

- Advantages: simple, established, and cost-effective.

- Limitations:

- Quality depends heavily on input feedstock.

- Contaminants remain — such as dyes, coatings, softeners, PFAS, or heavy metals.

- Microplastics are shed during processing.

- Fibers degrade over multiple cycles, reducing performance.

Chemical Recycling

- Process: polyester is depolymerized into monomers using glycolysis, methanolysis, hydrolysis, or enzymatic depolymerization. These monomers are purified and repolymerized into virgin-like polyester.

- Advantages:

- Produces high-quality rPET equivalent to virgin polyester.

- Can handle blended, dyed, and contaminated feedstocks.

- Supports closed-loop recycling that can be repeated multiple times.

- Risks:

- Uses chemical inputs like methanol and ethylene glycol.

- Emits volatile organic compounds (VOCs).

- May leave catalyst residues or contaminants if purification is inadequate.

Conclusion: While mechanical recycling offers a mature and economical solution, chemical recycling is essential for scalable, safe circularity in polyester textiles.

Managing Chemical Risks in Polyester Recycling

For chemical recycling to deliver on its promise, brands and suppliers must manage risks at every stage.

Common Contaminants in Feedstock

- Dyes and pigments

- Coatings, softeners, and plasticizers

- Restricted substances like PFAS, bisphenols, heavy metals, and phthalates

Risks from Chemical Inputs

- Solvents and VOCs: methanol, toluene, DMF, DMSO

- Catalyst residues from processing

- Wastewater containing toxic residues

Why Purification Matters

Purification steps like distillation, crystallization, and filtration are essential to remove hazardous chemicals and achieve safe, virgin-quality rPET. Without strict controls, recycling can transfer risks to workers, communities, and consumers.

- Garment workers and recyclers

- Surrounding communities and ecosystems

- Consumers wearing recycled textiles

How bluesign Ensures Safe Polyester Recycling

At bluesign, we help brands and suppliers adopt polyester recycling processes that are both circular and safe.

- Chemical management assessments ensuring all chemical inputs are properly managed.

- Purification system verification confirming contaminants are effectively removed.

- Emissions and wastewater monitoring to ensure strict safety standards.

- Compliance verification ensuring rPET meets the bluesign system black limits (BSBL), bluesign system substances list (BSSL), and global regulations like REACH and other industry standards such as AFIRM RSL.

With nearly 25 years of expertise, a global network of 970+ system partners, and a team of chemists and engineers, bluesign is uniquely positioned to help the industry scale polyester recycling responsibly.

The Path to Circular Polyester

The future of polyester recycling depends on scaling chemical recycling with robust chemical management. For brands and suppliers, this means:

- Integrate recycled polyester feedstocks into product lines.

- Collaborate with partners to ensure safe and compliant processes.

- Stay ahead of regulatory requirements with trusted verification.

By combining circular design strategies with clean chemistry, the textile industry can reduce its reliance on virgin resources while protecting people and the planet.

Key Takeaways

- Polyester recycling is critical to the circular economy, but chemical risks must be addressed.

- Mechanical recycling is limited; chemical recycling enables true closed-loop systems.

- Without purification, recycling can perpetuate toxic risks instead of eliminating them.

- bluesign provides expertise and verification to ensure safe, compliant, and scalable polyester recycling.

Discover how bluesign supports brands and suppliers in scaling safe polyester recycling — visit our sustainability solutions page for more.

Stay connected with bluesign

For more insights on sustainable textiles, chemical management, and industry regulations, follow bluesign on LinkedIn. Join the conversation and stay ahead of the latest developments shaping a safer, more sustainable textile industry.